Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

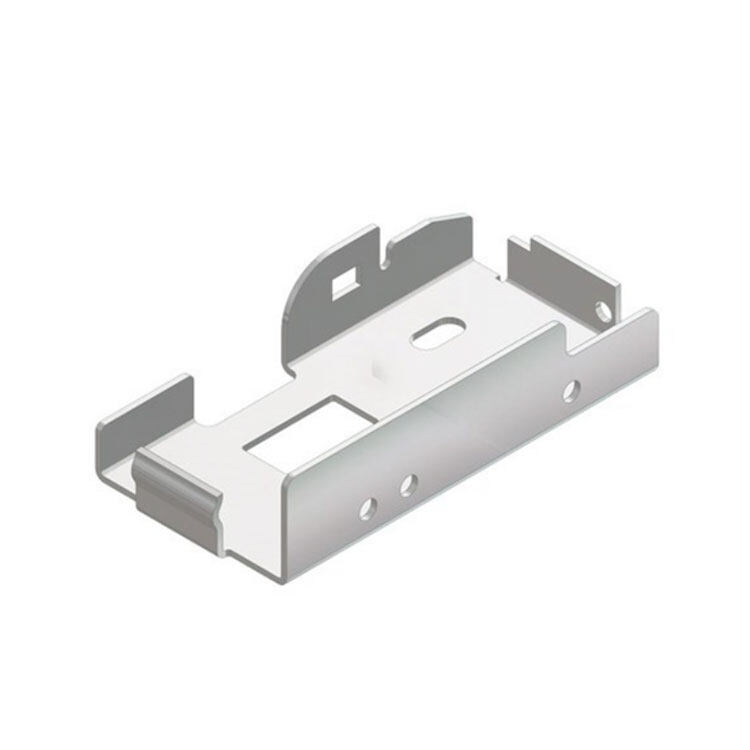

Laser Cutting Part

A wide range of items require the use of metal fabrication, which involves a combination of techniques like cutting, bending, and stamping. Runtian has tools and machinery that can be thoroughly processed.

Laser Cutting Part

Metal fabrication plays a crucial role in building a wide variety of products, the procedure uses a combination of processes, such as cutting, bending, and stamping. Runtian has machinery and equipment, which can be processed deeply.

The Standard Specification of Laser Cutting Part

|

Material |

Aluminum, Copper, Stainless steel, Iron, PE, PVC, ABS, Nylon, etc. |

|

Processing |

CNC Turning, Milling, drilling, auto lathe, tapping, bushing, surface treatment, etc. |

|

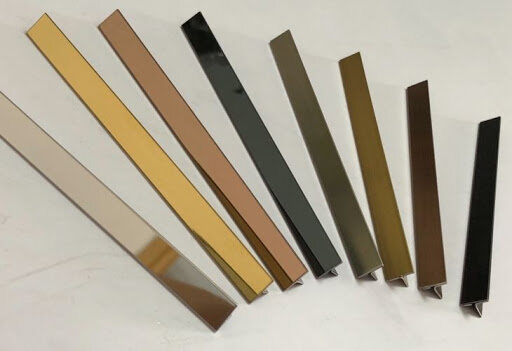

Surface Treatment |

Polishing, general/hard/color oxidation, surface chamfering, tempering, Sandblasting, Metal Plating, Polishing, Painting, Powder coating, Brushing, Silk-screen, Laser Engraving etc. |

|

Tolerance |

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form |

|

Logo |

Silk print, Laser marking |

|

Size |

Accept custom size. |

|

Color |

White, black, silver, red, grey, Pantone and RAL, etc |

|

Drawing format |

DWG, DXF, STEP, IGS, 3Ds, STL, SKP, Al, PDF, JPG, Draft. |

|

Sample lead time |

No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

The features of Laser Cutting Part

High flexibility, especially suitable for cutting small batches of 3D sheet metal materials. Its high flexibility is mainly manifested in two aspects:

1) Strong adaptability to materials, the laser cutting machine can basically cut any plate through the numerical control program;

2) The processing path is controlled by the program. If the processing object changes, only the program needs to be modified. This is especially evident when trimming and cutting holes in parts, because trimming dies and punching dies are helpless for the processing of other different parts, and the cost of molds is high, so laser cutting has replaced trimming dies and punching dies at present. the trend of.

The advantages of Laser Cutting Part

High cutting precision, good quality, small incision width, small heat-affected zone, smooth incision;

Fast cutting speed and high processing efficiency;

Laser processing is a kind of non-contact processing, which has no mechanical processing force, no deformation, and no pollution problems such as noise, oil, and processing chips. It is a green processing;

High material adaptability, almost any metal and non-metal materials can be cut.